Throughout the country Fall Hazards are still the NUMBER 1 cause for fatalities and injuries in construction. Because of this continuing trend, we are going to “dive” into the rescue portion of fall protection. No one wants employees to be involved in a fall, but if it happens, are you prepared for the results? Are you using a personal fall arrest system (PFAS)? Do you have the equipment to rescue? Have local emergency services been researched to determine they have proper equipment to rescue?

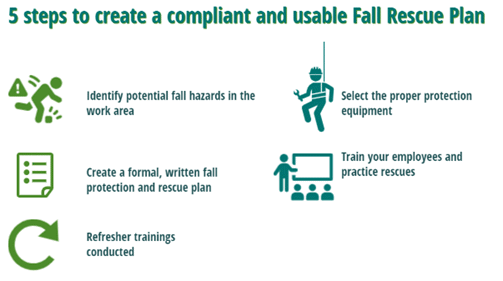

1. Identifying fall hazards in the work area(s) is easy, but not always simple to control. Prior to mobilizing to a project, discussions shall be conducted on proper site-specific safety requirements. Take the time to look at your working area before working. More times than not, you will not know about specific site hazards until the first day on the project. Communication is key!

2. Selection of proper protection equipment comes down to scope, not money. Don’t let this be the driving force on your equipment. Just like all PPE, make sure you are getting honest feedback from your employees. “Is it uncomfortable to wear 8+ hours? Does it fit properly (i.e. – too loose or too tight)? How do we know if it fits properly?”

Note: When it comes to full body harnesses, the “two (2) finger rule” still holds true. If the user can place two (2) fingers between the hip and chest straps, snugly, the full body harness is generally secured and tightened properly. Any additional space, the user shall tighten.

3. Creation of a formal, written fall protection and rescue plan does not happen during a fall. These are standard operating procedures (SOPs) that should be clearly outlined, having defined roles, and specific rescue used. Below are the three (3) most common rescue situations:

Self-Rescue (90% of most rescues happen with Self-Rescue):

If the person working at heights has properly selected and used their fall protection equipment, they may be able to perform a Self-Rescue, which should include the following steps:

- Climbing back up to the level from which they fell (from a few inches to 2-3 feet).

- Returning to the floor or ground to be evaluated for possible medical attention per OSHA.

- Remove all components of fall arrest system impacted by the fall event from service and document the components with name, date, and activity at time of fall and giving the equipment to management.

Assisted Rescue with Ladder:

- A rescuer will retrieve an extension ladder onsite.

- The extension ladder must be maneuvered into position (raised up underneath the fallen worker) so that the rescuer can perform the rescue.

- The employee(s) assisting with the rescue, positioning the ladder, will hold and secure the ladder at the base to ensure there is no accidental displacement.

- The fallen employee will then climb onto the ladder, remove all components of the fall arrest system, and lower themselves to the ground and provide medical aid as required by OSHA.

- Remove all components of fall arrest system impacted by the fall event from service and document the components with name, date, and activity at time of fall and give the equipment to management.

Assisted Rescue with Mechanically Aided Aerial Lift:

- A rescuer will get into the aerial lift and make sure there is a second fall protection device, such as a shock absorbing lanyard or self-retracting lifeline, available for the fallen worker.

- The lift must be maneuvered into position (raised up underneath the fallen worker) so that the rescuer can perform the rescue.

- Attach the second lanyard or self-retracting lifeline in the aerial lift to the fallen worker.

- Disconnect the rescued worker from the impacted fall arrest equipment.

- Lower the worker to the ground and provide medical aid as required by OSHA.

- Remove all components of fall arrest system impacted by the fall event from service and document the components with name, date, and activity at time of fall and give the equipment to management.

4. Train your employees and practice rescues routinely! If your work is presenting fall hazards, practice the steps in which it would take to rescue a worker. Per 29 CFR 1926.502, OSHA requires employers to "provide for prompt rescue of employees in the event of a fall.” What does “prompt” mean? OSHA goes on to say, “Prolonged suspension from fall arrest systems can cause orthostatic intolerance, which, in turn, can result in serious physical injury, or potentially, death. Research indicates that suspension in a fall arrest device can result in unconsciousness, followed by death, in less than 30 minutes.”

Activity: Gather all workers to delegate roles and responsibilities. Go over the intended rescue options for equipment and scope performed. Set timer at 30 minutes and start. Yes, it will be disastrous the first time, but think about the first time you “tried” to put on a full body harness, without ever using one. It will be new, uncomfortable, maybe confusing at times.

5. Refresher trainings shall be conducted at least annually and more frequently depending on scope. Although this phase has been modified over the years, Aristotle said it best: “it is frequent repetition that produces a natural tendency.” With that said, “natural tendency” can foster complacency, so review the plan at face value. If verbiage does not apply to your scope, take it out. At the end of the day, programs and policies are null and void if they cannot be physically translated on site.

All companies want their employees to go home to their loved ones at the end of each workday. With the information presented above, the creation of a Fall Rescue Plan should be a group effort, especially the front-line workers. Feedback and open communication are necessary during the creation and revision process. So, the next time you are working near or around fall hazards, ask yourself “If I fall, does my equipment REALLY have my back?”

Sources:

SHIB Suspension Trauma.Final.10.25.11.pmd (osha.gov)

Related Topics: Newsletter, Safety Facts and Snacks, Workplace Safety, Ladder Safety, Safety Hazards, Safety Culture, Safety Tips, Safety Programs, Jobsite Safety, Fall Protection