By: Shane Stuller

About Combustible Dust

Most natural and synthetic organic materials, as well as some metals, can form potentially deadly combustible dust. NFPA’s Industrial Fire Hazards Handbook states that "any industrial process that reduces a combustible material and some normally noncombustible materials to a finely divided state, present a potential for a serious fire or explosion."

Combustible dust is defined as a solid material composed of distinct particles or pieces, regardless of size, shape, or chemical composition, which presents a fire or deflagration hazard when suspended in air or some other oxidizing medium over a range of concentrations. Combustible dusts are often either organic or metal dusts that are finely ground into very small particles, fibers, fines, chips, chunks, flakes, or a small mixture of these. Types of dusts include, but are not limited to: metal dust, such as aluminum and magnesium; wood dust; plastic or rubber dust; biosolids; coal dust; organic dust, such as flour, sugar, paper, soap, and dried blood; and dusts from certain textiles.

The Dangers of Combustible Dust

While most of us are familiar with the standard “Fire Triangle”, a combustible dust explosion consists of five elements which is often referred to as the “Dust Explosion Pentagon”.

The first three elements that are necessary to initiate a dust explosion are those needed for a fire, i.e. the “Fire Triangle”:

1. Combustible Dust (Fuel)

2. Ignition Source (Heat)

3. Oxygen in air

The two additional elements needed for a combustible dust explosion are:

4. Dispersion of dust particles in sufficient quantity and concentration

5. Confinement of the dust cloud

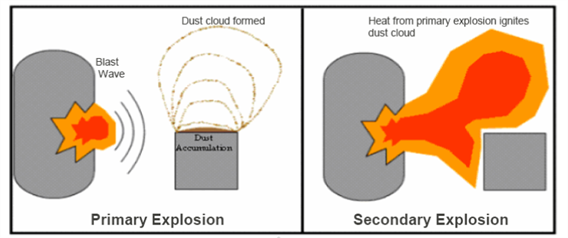

If one of these five elements is missing, an explosion cannot occur. In order for the explosion to occur, there is an initial, or primary, dust explosion in processing equipment which may shake loose accumulated dust, or damage a containment system (such as a duct, vessel, or collector). This causes the dust to become airborne and this additional airborne dust, if ignited, may cause one or more secondary explosions. These can be far more destructive than a primary explosion due to the increased quantity and concentration of dispersed combustible dust and the larger ignition source.

The ease of ignition and the severity of a combustible dust explosion are typically influenced by particle size. Other factors that influence the explosiveness of dusts include moisture content, humidity, oxygen available, the shape of dust particles, and the concentration of dust in the air. Different dusts of the same chemical material can also have different ignitability and explosibility characteristics, depending upon physical characteristics such as particle size, shape, and moisture content. These physical characteristics can change during manufacturing, use or while the material is being processed. Keep in mind though, that even weak explosions can cause significant damage, injury and death.

Methods of Protection

Facility Dust Hazard Assessments

Facilities should carefully identify the following in order to assess their potential for dust explosions:

- Materials that can be combustible when finely divided;

- Processes which use, consume, or produce combustible dusts;

- Open areas where combustible dusts may build up;

- Hidden areas where combustible dusts may accumulate;

- Means by which dust may be dispersed in the air; and

- Potential ignition sources.

Dust Control

- Below is list of recommended methods to help control dusts and prevent explosions:

- Minimize the escape of dust from process equipment or ventilation systems;

- Use dust collection systems and filters;

- Utilize surfaces that minimize dust accumulation and facilitate cleaning;

- Provide access to all hidden areas to permit inspection;

- Inspect for dust residues in open and hidden areas, at regular intervals;

- Clean dust residues at regular intervals;

- Use cleaning methods that do not generate dust clouds, if ignition sources are present;

- Only use vacuum cleaners approved for dust collection;

- Locate relief valves away from dust hazard areas; and

- Develop and implement a hazardous dust inspection, testing, housekeeping, and control program (preferably in writing with established frequency and methods).

Ignition Control

The use of proper electrical equipment in hazardous locations is crucial to eliminating a common ignition source. Below is list of recommended methods for ignition control:

- Use appropriate electrical equipment and wiring methods;

- Control static electricity, including bonding of equipment to ground;

- Control smoking, open flames, and sparks;

- Control mechanical sparks and friction;

- Use separator devices to remove foreign materials capable of igniting combustibles from process materials;

- Separate heated surfaces from dusts;

- Separate heating systems from dusts;

- Proper use and type of industrial trucks;

- Proper use of cartridge activated tools; and

- Adequately maintain all the above equipment.

Employee Training

While OSHA standards require training for certain employees, all employees should be trained in safe work practices applicable to their job tasks, as well as on the overall plant programs for dust control and ignition source control. They should be trained before they start work, periodically to refresh their knowledge, when reassigned, and when hazards or processes change.

Personal Protective Equipment

The importance of workers donning personnel protective equipment (PPE) takes on an added dimension with the threat from combustible dust fires and explosions in the workplace. Many manufacturing facility managers, owners, and employees are not aware of the fire hazard from combustible dust. In environments where workers can sustain life threatening burns from vapor cloud explosions and flash fires, such as in the refinery sector, Flame Resistant clothing is required.

A combustible dust explosion hazard may exist in your workplace, especially if you are in the food, plastics, wood, rubber, furniture, textiles, pesticides, pharmaceuticals, dyes, coal, metals, fossil fuel power generation or one of many other industries that processes, handles, stores or transports materials or byproducts in fine, powdery form. If so, your workers could be at risk and the applicable Federal, state, local laws and OSHA regulations must be identified and followed. A team of qualified managers or supervisors should be responsible for conducting the facility assessment (or for having one done by qualified outside persons) prior to the introduction of a hazard and for developing a prevention and protection scheme tailored to their operations. All personnel should be aware of and support the plant dust and ignition control programs.

References: National Fire Protection Association (NFPA). “Industrial Fire Hazards Handbook,” 3rd Edition. NFPA, Inc., Quincy, MA, 1990. OSHA Combustible Dust Safety and Health Topics Page (www.osha.gov/dsg/combustibledust/index.html):

- Combustible Dust National Emphasis Program Instruction, OSHA Directive CPL 03-00-008, (2008).

- Safety and Health Information Bulletin (SHIB) (07-31-2005) Combustible Dust in Industry: Preventing and Mitigating the Effects of Fire and Explosions.

- OSHA Fact Sheet, (March 2008), Hazard Alert: Combustible Dust Explosions.

- OSHA Poster (2008), Combustible Dust.

Related Topics: Combustible Dust, Monthly Safety Topics, Safety Articles