By: Karl Weisser

March 2015

The Electric Power Generation, Transmission, and Distribution and its Electrical Protective Equipment standards have not been updated since OSHA began in the early 1970s. This previous standard is inconsistent, ineffective, and out of date. Since then, there have been many technological advances in safety awareness’s for both construction and general industry. The final rule for this standard will unify construction and general industry standards together to help create a consistent and innovative set of requirements. Employers following these rules will effectively establish work practices to protect their workers. The rules will include new or revised provisions on host employers, contractors, job briefings, training, fall protection, personal protective equipment, working positions of employees on or near live parts and many other regulations to better protect workers from electrical hazards.

Overall, OSHA is revising the following federal regulations in the General Industry and Construction standards:

- PART 1910

- Subpart I – Personal Protective Equipment

- Appendix B to Subpart I of Part 1910 – Nonmandatory Compliance Guidelines for Hazard Assessment and Personal Protective Equipment Selection

- Subpart R – Special Industries

- Subpart S – Electrical

- Subpart I – Personal Protective Equipment

- PART 1926

- Subpart A – General

- Subpart E – Personal Protective and Life Saving Equipment

- Subpart M – Fall Protection

- Subpart V – Electric Power Transmission and Distribution

- Subpart X – Stairways and Ladders

- Subpart C – Cranes and Derricks in Construction

The new requirements regarding host and contractor employers now specify both employers to notify and exchange important information on the hazards and the conditions, and characteristics of the host employer’s installation. These new rules also mandate the employers to coordinate their work rules and procedures to protect all employees (workers). This includes, but is not limited to a job briefing prior to each day or shift. The prejob briefing shall cover at least the following subjects: Hazards associated with the job, work procedures involved, special precautions, energy-source controls, and personal protective equipment requirements as required by § 1926.952 of the final rule.

The training revisions add requirements for the degree of training to be determined by the risk to the employee for the hazards involved. Some other significant changes to the training regulations include that qualified workers must have training to recognize and avoid/control electrical hazards, line-clearance tree trimmers must be trained to distinguish exposures to live parts and determine the voltage if exposed. In accordance with § 1926.950, each qualified employee shall be trained and competent in the skills and techniques necessary to distinguish exposed live parts from other parts of electrical equipment, determine the nominal voltage of exposed live parts, know and understand the minimum approach distance in this subpart corresponding to the voltages to which they will be exposed, and the proper use of techniques, personal protective equipment, and insulating and shielding materials.

Fall protection provisions have been revised to include new requirements for the use of fall restraint systems and personal fall arrest systems in certain situations. There are three main types of fall protection equipment that standards requires; depending on the situation, the employee may have to use a personal fall arrest system, a fall restraint system, and work-positioning equipment such as a body belt or a body harness system rigged to allow support on an elevated vertical system such as a utility pole. The standard now requires employers to protect employees who are working at 4 feet or higher on an elevated working surface. On April 1st, 2015, the final rule requires “each qualified employee climbing or changing location on poles, towers, or similar structures must use fall protection equipment unless the employer can demonstrate that climbing or changing location with fall protection is infeasible or creates a greater hazard than climbing or changing location without it.”

Personal Protective Equipment (PPE) standards between General Industry § 1910.137 and Construction § 1926.97 are harmonized to help protect workers who deal with the hazards of electricity. A few new provisions include the design requirements for specific types of electrical protective equipment must include the manufacture and marking of rubbing insulating equipment. The final rule also recognizes Class 00 as rubber insulating glove, as a new class of electrical equipment.

One of the biggest concerns of this new requirement is for electrical footwear as a supplementary form of protection. “Electrical-hazard or dielectric footwear would be required as a supplementary form of protection when an employee standing on the ground is exposed to hazardous step or touch potential (the difference in electrical potential between the feet or between the hands and feet) or when primary forms of electrical protective equipment, such as rubber insulating gloves and blankets, do not provide complete protection for an employee standing on the ground” (Occupational Safety and Health Administration, 2014).

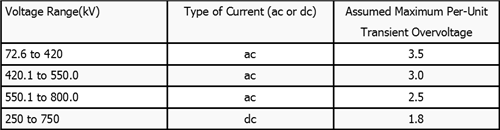

The final rule has required the employer to establish a minimum approach distance that the employees must follow and maintain from exposed energized parts. The employer may determine the maximum anticipated per-unit transient overvoltages through engineering analysis, or assume certain maximum anticipated per-unit transient overvoltages. April 1st, 2015, is when the revised minimum approach distance comes into effect. Below is attached the following table in accordance with the final ruling minimum approach distance:

For protection from electrical arcs, the new provisions include that the employer must assess the workplace to identify any exposure to flames or electrical hazards. In addition to assessing the workplace, protection from flames and electrical arcs must be in place by April 1st, 2015. Employers are also required to provide workers with protective equipment with an arc rating greater than or equal to the estimated heat energy they employees are going to working around.

Protective grounding to de-energize parts over 600 volts will continue to require live line tool. Under the new standard, the application of protective grounding now permits employers to install and remove protective grounds on lines and equipment operating at 600 volts or less without utilizing a live line tool under special conditions. “For example, an insulator on a power line could be replaced by an employee using live-line tools or rubber insulating equipment or by an employee working without electrical protective equipment after deenergizing and grounding the line. The employee would only need to be trained in the method actually used to replace that insulator” (OSHA, 2014).

The final rule has come into effect on July 2014, but there are many standards and requirements that are not being fully enforced until early 2015. This new up-to-date ruling, will greatly improve the safety and health for workers that are involved in the industry. OSHA has estimated that an average of 74 fatalities and 444 serious violations occurs annually among employees involved in the electric power generation, transmission, and distribution work. Along with this final rule it will prevent approximately 19.75 additional fatalities and 118.5 additional serious injuries annually. With the skills and quality performance Safety Resources Inc. provides, your company is capable of complying with all new rules being set in place and becoming role models of excellence.

Hajian, A. (2014). The Bigger Picture: Electric Power Generation, Transmission, and Distribution and Electrical Protective Equipment Final Rule. Electric Energy T&D Magazine, 47-50.

Department of Labor Occupational Safety and Health Administration. (2014). Electric Power Generation, Transmission, and Distribution; Electrical Protective Equipment, 6-9, 120, 1204. Retrieved from http://www.dol.gov/find/20140401/2013-29579.pdf

Department of Labor Occupational Safety and Health Administration. (2014). Electric Power Generation, Transmission, and Distribution; Electrical Protective Equipment Final Rule. OSHA Fact Sheet, 1-3.

Related Topics: OSHA, Electric Power Generation, General Industry and Construction Standards, Monthly Safety Topics, Safety Articles