By: Ryan Bruner

There are unspoken little wins celebrated among the HSE community when hazards are lessened or removed in a given process. We can all agree that there are certain levels of control methods, some more effective than others, helping with those little wins. Although the overall choice of control tends to be confusing, especially if there are processes needing to be re-assessed for overseen hazards. Controls can become less confusing and cumbersome when we breakout the specific hazard itself. Below are some quick tips for choosing and implementing the correct Engineering, Administrative and PPE controls for your process or task through hazard recognition and work assessment.

Tip 1: Recognize potential or existing hazard(s)

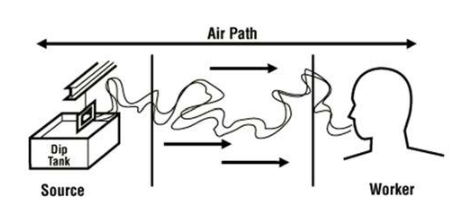

How do we identify our hazards? Let’s go back to our 100-level safety coursework and use the tried and true JHA (or Job-Hazard Analysis). “Put every task under a microscope,” they say. That’s the easy part, you might be saying to yourself. You want to know, how to reverse the effectiveness, from least to most, if a Prevention through Design (PtD)® directive or safety through design (i.e. - utilizing controls through the design and creation process) has not been implemented. In the picture below our source is at the “Dip Tank.” This is going to be the location we focus all our efforts on either isolating (engineering control), formulate new work practices (administrative control) and/or requiring PPE.

Tip 2: Identify hazard source(s)

Hazards are found and controlled “at the source (where the hazard "comes from"), along the path (where the hazard "travels") or at the worker.” (Government of Canada, Canadian Centre for Occupational Health and Safety, 2018). Physical demands, equipment and materials all pose as potential hazards within the workplace, most likely on a repetitive basis. When looking at the “Hierarchy of Controls” triangle, elimination and substitution are the most advantageous controls we can adopt, but not always practical or feasible.

Tip 3: Determine Control

Let’s look at a basic example involving a baseball catcher. A baseball catcher uses personal protective equipment during each game:

Helmet

Face-shield

Chest protector

Leg guards

Baseball mitt

Although we don’t classify the equipment as such, this PPE is the last line of defense against any baseball-related hazard. Although the PPE is established, there is the still a chance of that catcher to be hit by a ball. How do we mitigate that potential? Can we correct the catcher’s perceived risk by “controlling” the risk? Yes! Think of the administrative control in this scenario as the rules of the game of baseball: Where is the catcher allowed to stand? When can they catch the ball?

Now, how do we reduce the source of exposure? This is where engineering comes into play. It is not used, but we could implement a net or screen to be placed between the catcher and person at bat. This would be an engineering implementation.

With these three tips, mentioned above, we can have an idea of how and when we should classify or identify our control necessary for our process or task, by

1. Recognize potential or existing hazard(s)

2. Identify hazard source(s)

3: Determining the Control.

Government of Canada, Canadian Centre for Occupational Health and Safety. (2018, February 16). Hazard Control: OSHA Answers. Retrieved February 16, 2018, from http://www.ccohs.ca/oshanswers/hsprograms/hazard_control.html

Related Topics: Monthly Safety Topics, Safety Tips, Safety Hazards