Staying Safe This Winter

The construction industry is a year-round endeavor. During these specific times of the year, as outside temperatures begin to drop, implementing measures to maintain a relatively warm work environment are necessary for certain operations and worker’s comfort.

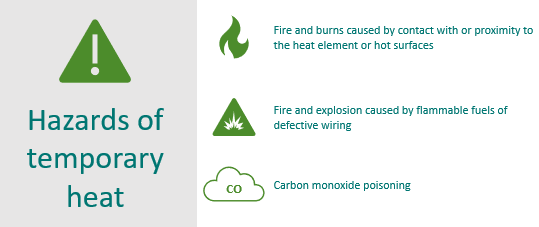

Each year, construction site fires occur due to improper selection, setup, use and management of temporary heating devices. Construction fires can lead to significant or total property loss, as well as personal injuries. Fire risks increase when temporary heaters, even those properly selected and setup, are left running continuously or left unattended. Given the hazards temporary heaters can present, it is key to ensure the proper preparation, implementation, and monitoring within the project site.

Preparation: Specific project operations should be considered when selecting your means of temporary heat. Confined space work or tasks involving welding may be impacted by atmospheric hazards such as exhausts fumes or vapors. The project may also be exposed to a potential fire hazard if temporary heating devices are positioned in areas with poor housekeeping or cluttered with waste debris. With the presence of an ignition source, materials should be stored away from the sides and rear, of the equipment, at a minimum of thirty-six (36) inches. Any type of tarp, canvas, or other combustible coverings should be at least 10 feet away and secured to prevent them from catching fire.

Not only could combustible materials ignite but employees may be exposed to burn injuries if they come into direct contact with the heating unit. The equipment should be inspected regularly for proper operation, leaks, and/or any other malfunctions, which should be corrected immediately. Equipment must be cleaned and maintained on a regular schedule to reduce the accumulation of dust and other potentially ignitable materials. All equipment and fuel sources are required to be labeled with the required hazard identifications.

Implementation: The position of the heating equipment is crucial in preventing fires and injuries. Heating devices should always be set horizontally or however otherwise permitted by the manufacturer. They are required to be placed on at least 1-inch of concrete or other suitable surfaces which will not increase the likelihood of a fire. Pathways should not be blocked, and devices are not permitted to be placed near or within stairwells. Safe means of exit must be maintained to ensure emergency egress points are not compromised.

Along with equipment positioning, the placement of the fuel source should be evaluated. A commonly used fuel source, for heating purposes, is liquid propane (LP) gas. Due to the presence of an explosive material, LP containers should be positioned away from any buildings or other operations based on total weight. Tanks consisting of five hundred pounds or more should be positioned, at the minimum, ten feet from the building. As weight increases, so will the distance from the building. Depending on the location of this tank, if exposure to vehicle strikes may be possible, some means of protection must be provided. The simplest form of protection is achieved by the placement of physical barriers such as bollards or even temporary means. The final piece of protecting this fuel source is by having a properly rated fire extinguisher located in the area.

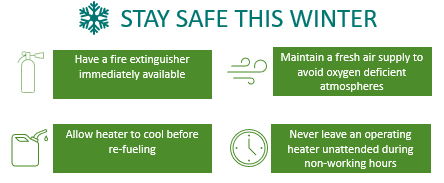

Monitoring: Every year, there are workplace deaths caused by carbon monoxide poisoning. Symptoms of carbon monoxide exposure can include everything from headaches, dizziness and drowsiness to coma or death. Usage of a proper ventilation system and avoidance of using fuel-burning equipment in enclosed or partially enclosed spaces can reduce teh risk of carbon monoxide poisoning in the workplace.. Carbon monoxide detectors are a viable option for monitoring of suspected hazardous areas. Ventilation can be achieved by forced movement of air through fans or by simply allowing windows and exterior doorways to be opened in areas with natural air flow.

In addition to monitoring the equipment, fire protection must be maintained and monitored monthly. A properly rated fire extinguisher should be readily available near each heat source. These should be fully charged and easily accessible.

To learn more about how to keep your projects safe, when dealing with temporary heaters and numerous other issues, visit our Safety Services to find out how our we can help you.

Related Topics: Workplace Safety, Fire Prevention, Safety Hazards, Heat Safety, Winter Safety, Jobsite Safety, Safety Awareness, Construction Safety, Monthly Safety Topics, Safety Articles